Transform Your Ideas into Reality with Premium Plastic Prototype Service

In today's fast-paced business environment, innovation is the key to survival and success. Companies are continuously on the lookout for ways to streamline their product development processes and bring their ideas to market faster. One integral part of this process involves plastic prototype service, which has revolutionized how businesses conceptualize, develop, and test their products. With the right partner, like DeepMould, you can ensure your ideas take form with precision and efficiency.

Understanding Plastic Prototyping

Plastic prototyping involves creating a physical model of a product using plastic materials. This process helps businesses visualize and evaluate their products before they go into mass production. Unlike traditional manufacturing, plastic prototyping offers rapid turnaround times, allowing for swift iterations and modifications during the design phase.

Why Choose Plastic Prototyping?

- Speed: Plastic prototypes can be produced significantly faster than metal prototypes, enabling quicker feedback and iteration.

- Cost-effectiveness: Creating plastic prototypes is generally less expensive than metal fabrication, making it a budget-friendly option for businesses of all sizes.

- Flexibility: Plastic materials allow for a wider range of shapes, textures, and colors, offering design flexibility that metals cannot achieve as easily.

- Testing and Validation: Rapid prototypes provide a tangible product for testing functionality, ergonomics, and user experience.

Key Benefits of DeepMould's Plastic Prototype Service

Choosing a reliable partner for your plastic prototype service is crucial. At DeepMould, we pride ourselves on offering state-of-the-art services that take your product from concept to prototype seamlessly.

1. Advanced Technology

We utilize advanced technologies such as 3D printing, CNC machining, and injection molding to create prototypes that accurately reflect your design specifications. Our cutting-edge tools ensure high precision and repeatability, providing prototypes that feel and perform like the final product.

2. Expertise and Support

Our team of experienced engineers and designers are here to support you throughout the prototyping process. From initial design consultations to final prototype adjustments, we offer expert advice tailored to your unique needs. This expertise not only enhances the quality of the prototypes but also saves valuable time during development.

3. Rapid Turnaround Time

In the world of business, time is critical. Our plastic prototype service is designed for speed; we aim to deliver high-quality prototypes in days, not weeks. This rapid turnaround allows you to test and iterate your designs efficiently, keeping your projects on schedule.

4. Comprehensive Solutions

At DeepMould, we provide end-to-end solutions for your prototyping needs. From initial concept sketches to detailed designs and final prototypes, we cover every aspect. This comprehensive approach minimizes the risk of miscommunication and ensures that your vision is realized with utmost precision.

Industries That Benefit from Plastic Prototyping

The versatility of plastic prototyping means that it can be applied across various industries. Here are some key sectors that benefit from our plastic prototype service:

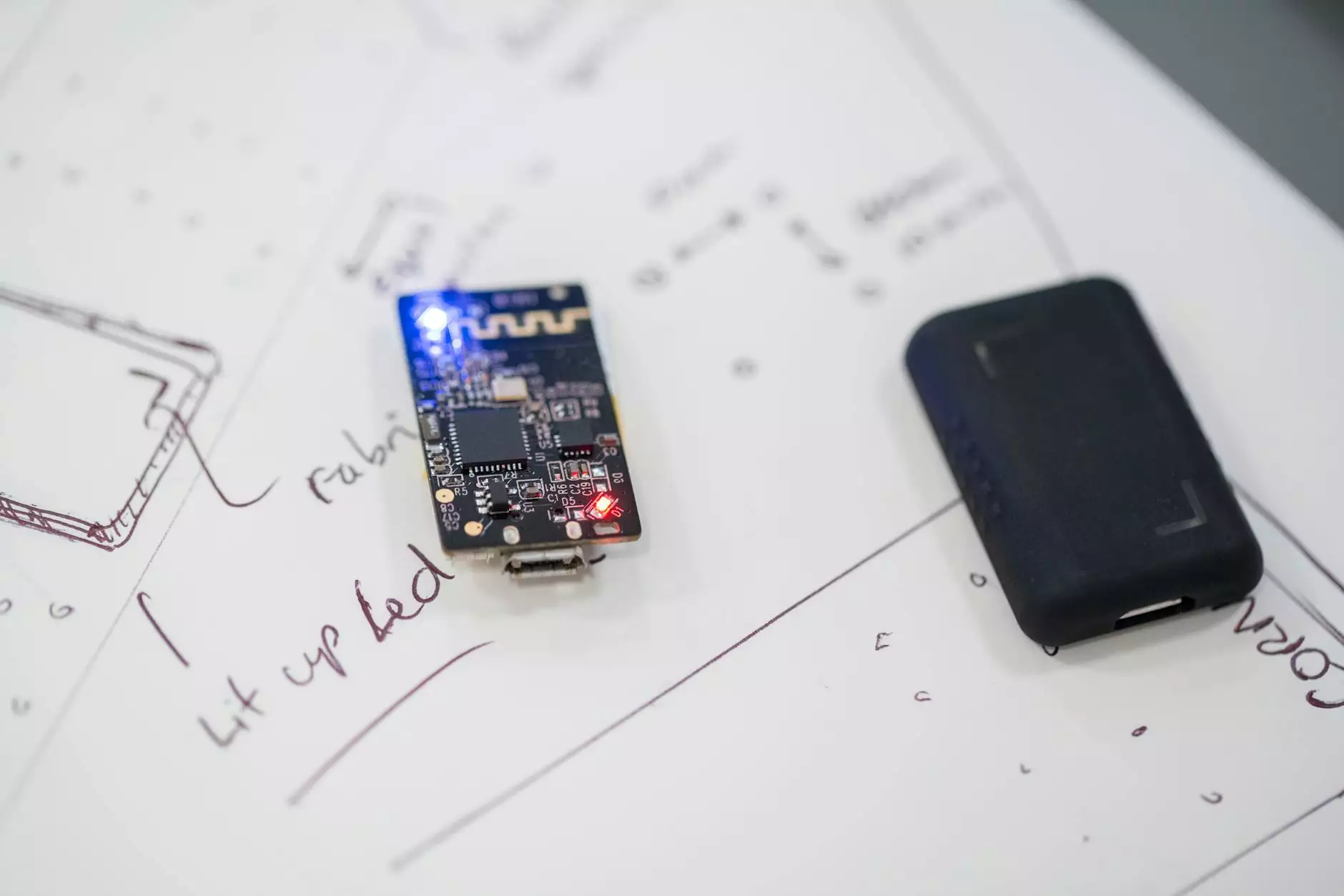

- Consumer Electronics: Companies in this sector often require rapid prototyping for complex parts, ensuring functionality and ergonomics before production.

- Automotive: Plastic prototypes are essential in designing interior components and testing user interfaces.

- Medical Devices: The medical industry demands precision and reliability. Prototyping aids in designing essential products like surgical instruments and diagnostic devices.

- Consumer Goods: Quick market entry is vital for consumer products; prototyping speeds up the design process for packaging, containers, and other goods.

How to Get Started with DeepMould’s Plastic Prototype Service

Getting started with our plastic prototype service is easy. Here’s a step-by-step guide to help you through the process:

Step 1: Consultation

Reach out to us via our website or contact numbers. Our team will schedule a consultation to understand your project needs, objectives, and timelines.

Step 2: Design Submission

Once we have discussed your requirements, you will need to provide your design files. Whether you have detailed CAD models or sketches, we can work with you to refine them into a workable design.

Step 3: Prototype Production

Our engineers will start working on your prototype, employing the latest technology to ensure accuracy and quality. We will keep you updated on the progress to ensure that everything meets your expectations.

Step 4: Review and Feedback

Upon completion, you will receive the prototype for evaluation. We encourage you to test it thoroughly. Your feedback is essential for making any necessary adjustments.

Step 5: Final Adjustments and Delivery

Based on your feedback, we will make final adjustments to the prototype. Once you are satisfied, we will deliver your high-quality plastic prototype, ready for your next steps towards production.

Quality Assurance at DeepMould

Quality is at the heart of everything we do. We utilize rigorous testing and quality control processes to ensure that every prototype meets industry standards. Our commitment to excellence means that you receive not just a prototype, but one that can be trusted for accuracy and reliability.

Conclusion: The Future of Product Development with DeepMould

In conclusion, embracing a plastic prototype service is a game-changer for businesses aiming to bring innovative products to market. DeepMould offers unparalleled expertise, advanced technology, and a comprehensive approach to prototyping. By partnering with us, you can transform your ideas into reality while saving time and resources.

Are you ready to take your product from concept to completion? Contact DeepMould today to learn more about our plastic prototype service and discover how we can help you achieve your business goals.